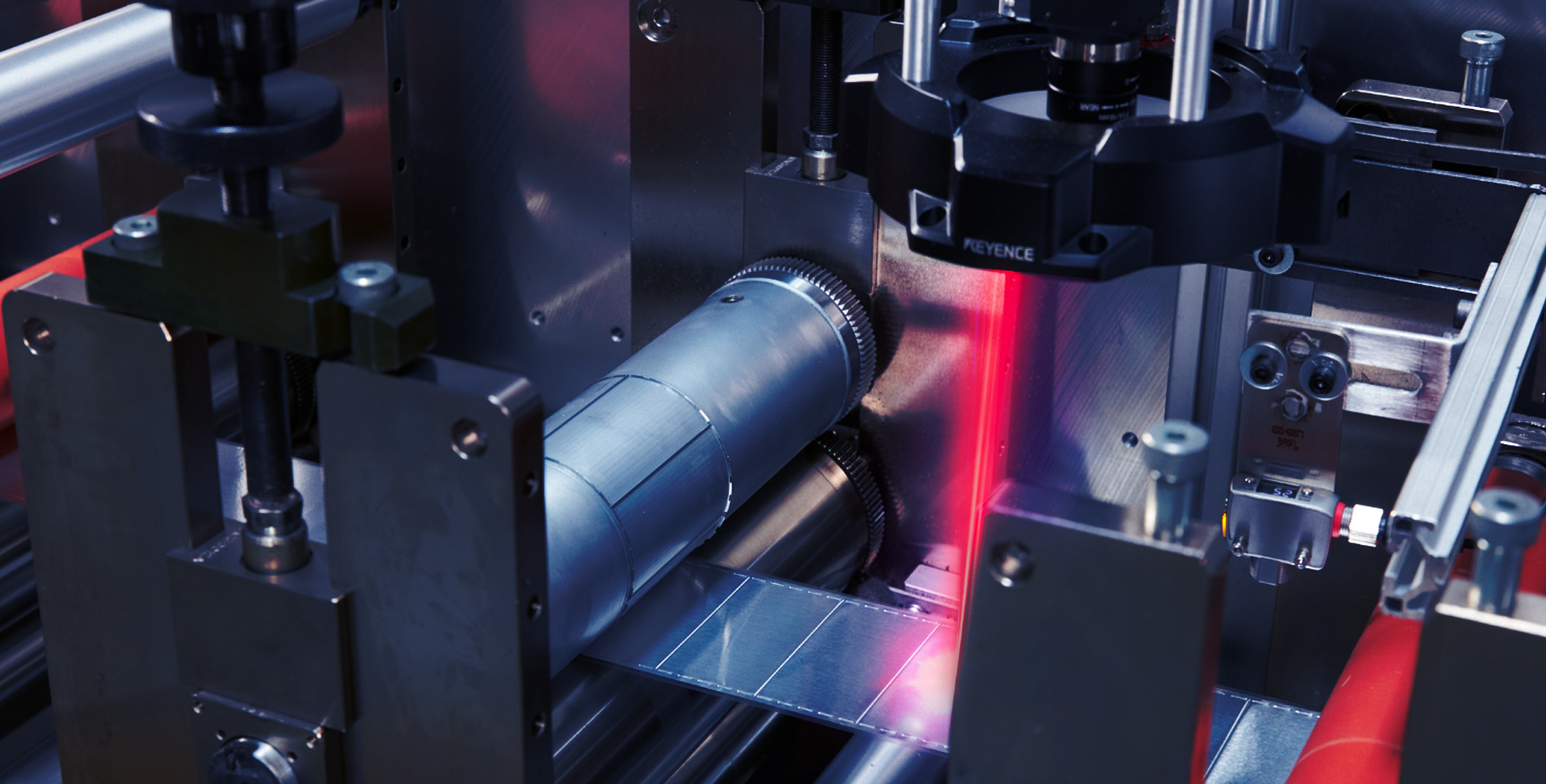

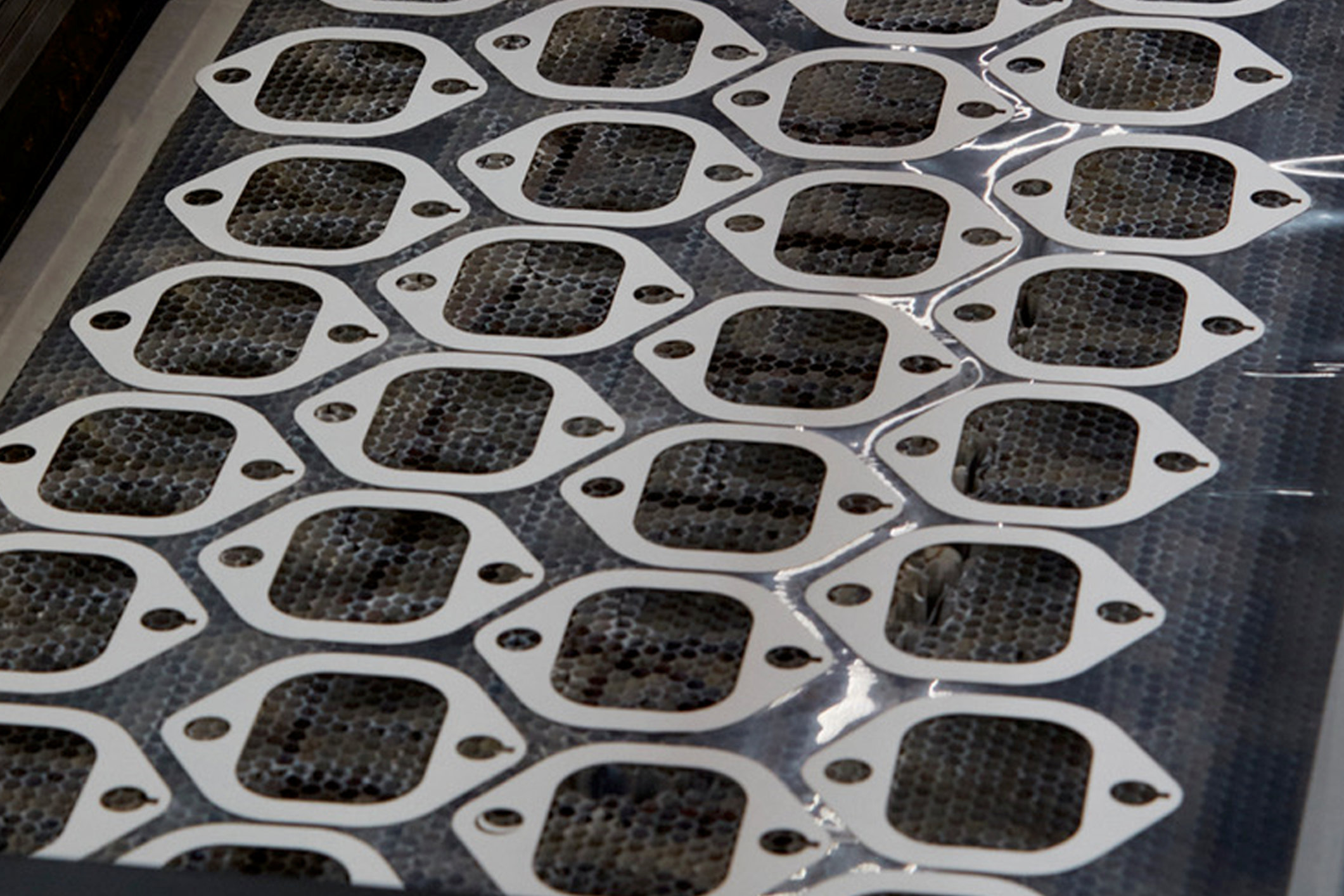

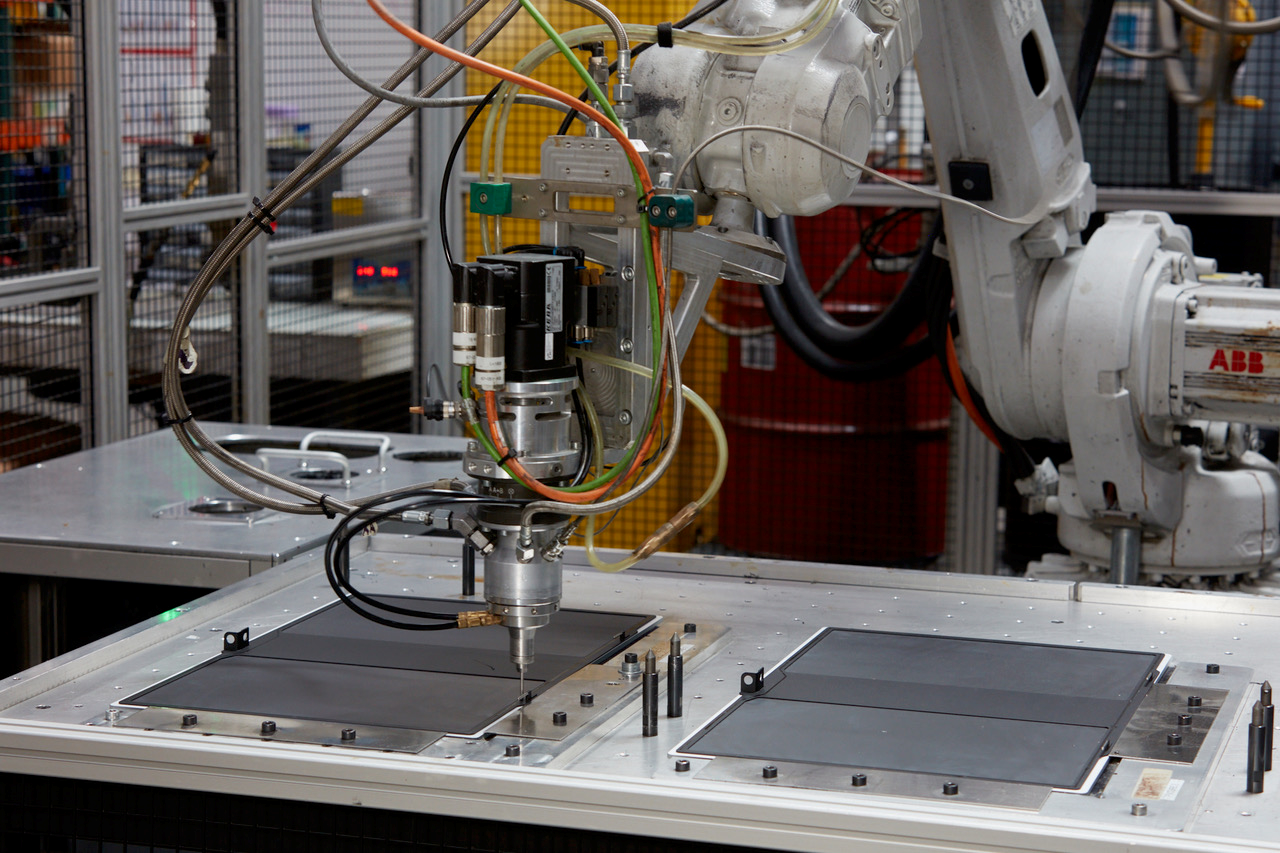

Seal Methods Inc is a full-service fabricator of gaskets, seals, tapes and precision die cuts. We are one of the most diversified converters in the industry and offer a variety of manufacturing capabilities driven by our knowledgeable engineering and teams. This combination helps make us a leading solutions provider and custom materials converter in North America. With multiple facilities, our capabilities include custom converted parts manufactured with rotary and flat stamp die cutting, multi-layer laminations, water-jet and laser cutting, foam in place gasketing and so much more!

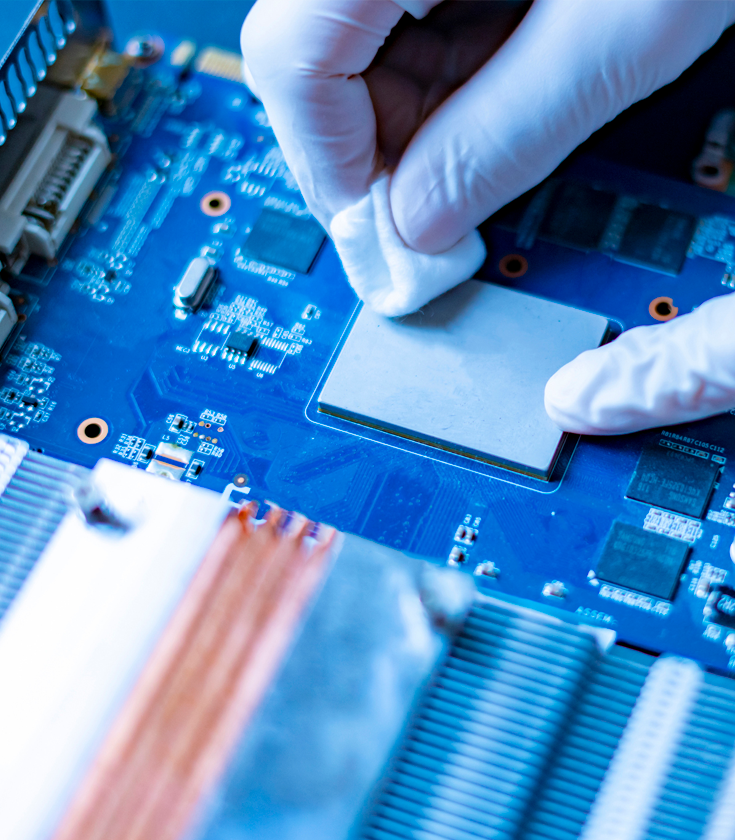

SMI specializes in using materials ranging from basic sponge or rubber to high performance elastomers, foams, films, plastics and pressure sensitive adhesives. We work closely with our clients to prototype and manufacture custom applications, whether you need a simple cushion or adhesive tape, or high-performance gaskets, seals, insulators or thermal barriers.

Our ability to create rubber, foam and plastic parts stretches beyond precision cutting of rolls or sheets. We can perform injection or compression molding as well as custom extrusions that are used in an array of industries.