Our History

Founded in 1974 by Gene Welter, Seal Methods, Inc. (SMI) is a full-service premier fabricator of gaskets, seals, tapes and precision die cuts. We are one of the most diversified converters in the industry.

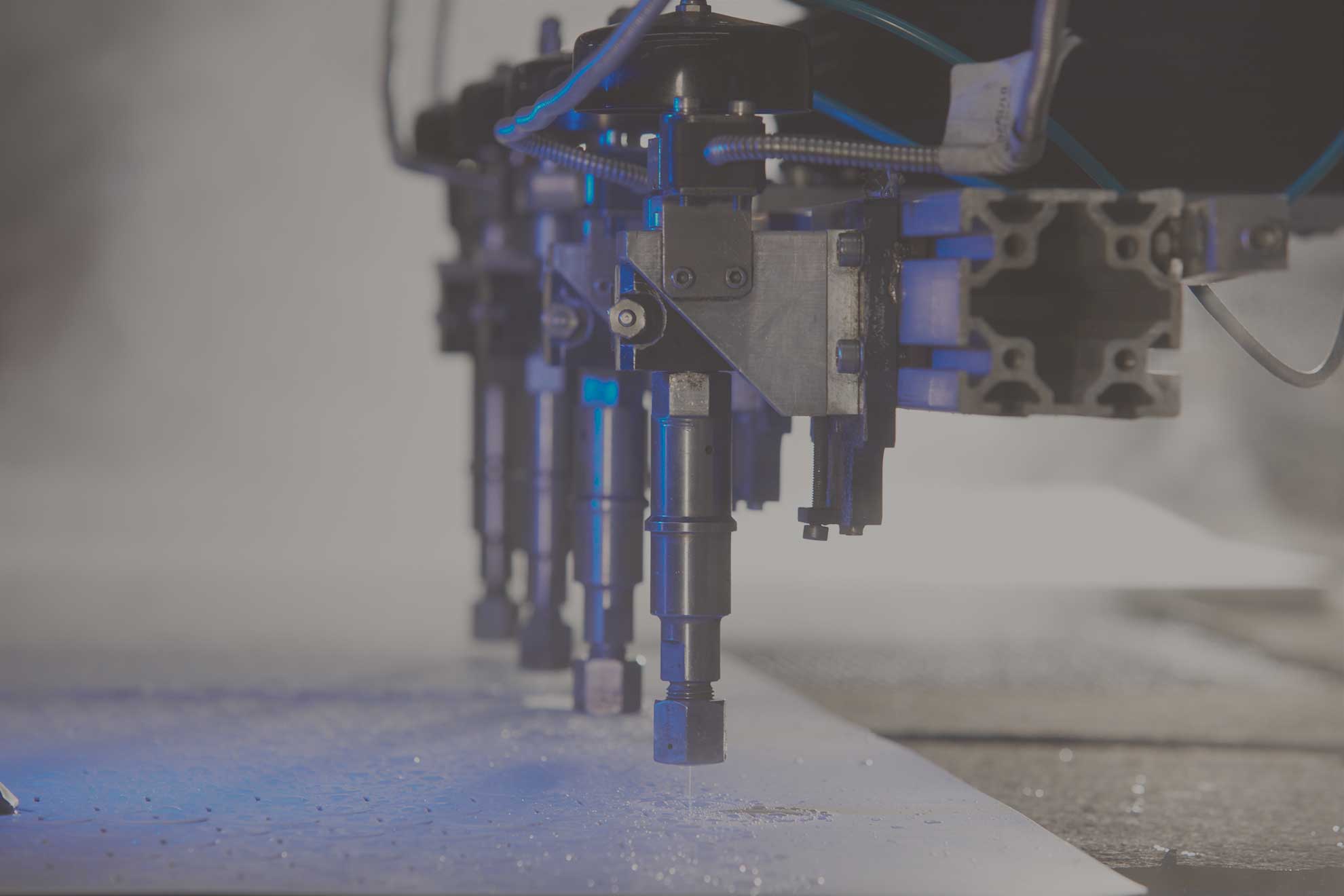

Seal methods Inc, privately held and family run, has grown into one of the most diversified materials converters in the country. With multiple facilities around the world, we are a custom converter, manufacturing rotary and flat stamp die cuts, multi-laminations, water-jet, and laser cut materials.

SMI specializes in using materials ranging from sponge or rubber to high-performance elastomers, foams, films, plastics and pressure sensitive adhesives. We work closely with our clients to prototype and manufacture custom applications, whether you need a simple cushion or adhesive tape, or high-performance gaskets, seals, insulators or thermal barriers.